Movie blockbuster The Hunger Games starring Jennifer Lawrence created a surge of interest in the ancient sport of archery. The movie was also one of the sources of inspiration behind the Gorilla Bow, a unique piece of fitness equipment that was created by SIGMA OEM salesman Tom Whittington and a business partner Chris Caouette.

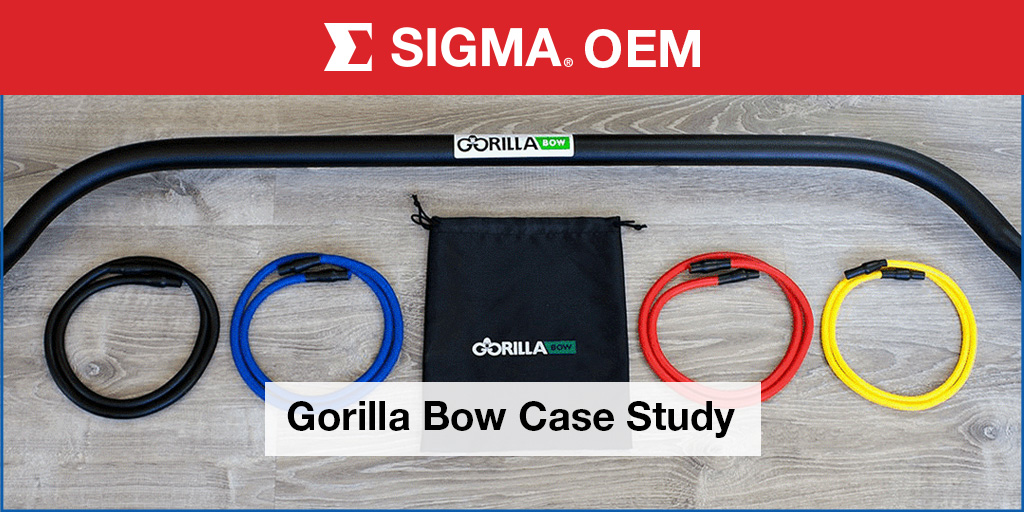

Tom and Chris were both keen archers and realized that archery is a surefire way to increase upper body strength. After brainstorming the idea and consulting friends, family, and fitness pros, they developed a prototype of the gorilla bow. By incorporating traditional latex resistance bands in their design, they created a portable exercise machine capable of delivering a total body workout equivalent to working out with weight machines loaded with anywhere from 10lb to 300lbs.

Tom who is himself an avid fitness buff explains: “We built the first prototype in Chris’s garage using aluminum conduit pipe and a pipe bender. We assembled it using wood, fiberglass and small metal brackets bought at Home Depot. We proved the concept by using the product and getting rave feedback, but ended up breaking this prototype in the process. It was a lousy prototype come to think of it, but it provided proof of concept. For our second prototype we tested the bow out in a couple of gyms and developed a series of total body fitness exercises for the bow. The reviews were all very positive. We then found a local machine shop to produce the claw, which anchors the resistance bands at either end of the bow and incorporated aluminum aircraft pipe that was bent into shape and welded by a fabricator.”

The partnership then undertook even more test studies by seeding the prototype product with gyms and fitness pros. Once they were happy with the model they, worked with SIGMA OEM to put the product into full-scale production. Working with SIGMA OEM in China, Tom was able to use the die cast process to produce the claw. Further, by avoiding machining and going the route of die cast molding instead, Tom was able to save 75% on his machining costs. “The product has really taken off,” says Tom, “We do most of our advertising on Facebook, YouTube and Google Ads, and are now an Amazon Prime approved retailer. At our peak we are moving 50 units a day. Not only have we had interest in the Gorilla Bow from the fitness market, but also healthcare professionals have been in touch and are using the bow in their physical therapy practices.”

At $149.99, the gorilla bow represents good value for money, and unlike free weights it is portable. Based on feedback from their customers, Tom and Chris are developing a version of the gorilla bow that can be broken down and packed in a travel suitcase. Once again they plan to work with SIGMA OEM on its manufacture.

“Another good thing about working with SIGMA is that they handle all manufacturing, quality and logistics and we receive our product just in time, thus taking the worry out supplier management and freeing up our time to work on marketing and sales. Fortunately, up to now, we cannot keep stock in the SIGMA warehouses as we’re selling 50 gorilla bows a day and can’t ship them out of the warehouse fast enough – but it’s good to know we have that option if we need it. It is peace of mind knowing SIGMA has taken the worry out of sourcing my product.”

For further information see www.sigmaoem.com or tom@gorillabow.com