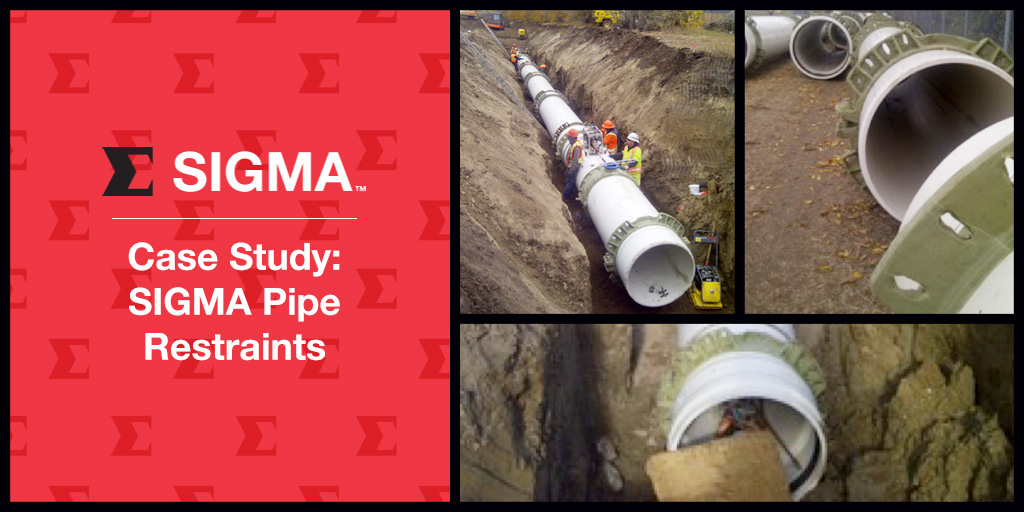

The City of Saskatoon in Saskatchewan, Canada needed to expand its water supply to serve its growing population. The new 1050mm diameter fill main was designed to bring water from a treatment plant to a local reservoir as a supplemental water supply to remote areas of the City.

The project was a complicated one for several reasons. First, the pipeline had to traverse an area used by Agriculture and Agrifood Canada (AAFC) for agriculture research. Construction and installation had to be completed between crop cycles, and the schedule also had to avoid the migratory birds’ mating season. This allowed three months to install 1200m of pipe with two 90 degree bends and a section that required boring a tunnel under the road. The second challenge involved corrosion resistance. Buried metal is always subject to corrosion, and a pipeline this important needed an especially long life span. SIGMA had to devise a way to protect the restraints from degrading over time.

Both challenges were met using efficiency and innovation. To address the timeframe challenge, SIGMA organized the sourcing, shipping and delivery process for maximum efficiency, ensuring that all materials were onsite in the proper sequence for the construction schedule.

To address the corrosion concern, SIGMA used innovation. They coated the restraints with Denso tape and paste, a petroleum-based product that is impregnable to water. This approach required more steps in the process than a typical restraint job would, but it ensures that the pipeline will last long into the future.

The project was successfully completed on time and on budget.

For information on SIGMA Pipe Restraint Products, please contact Steve McDonald at smd@sigmaco.com.