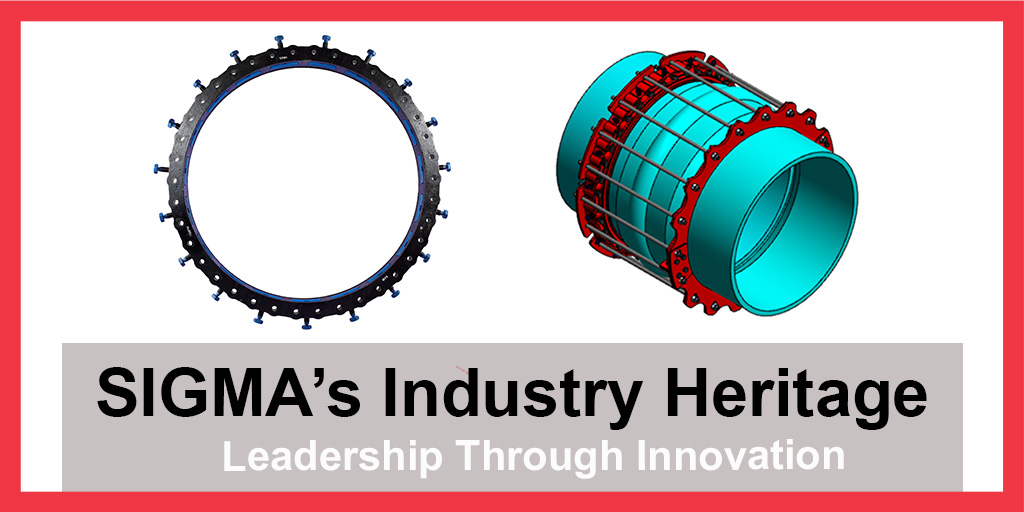

Over the last 20 years, SIGMA has continued a tradition of innovation in the water and wastewater industries. The company lays claim to a number of firsts, especially in the arena of pipe restraint products. Many new mechanical innovations have been introduced following requests from waterworks customers. While competitors have preferred to tread water and view restraints as a commodity product, SIGMA’s engineering team has worked hand in hand with its distributors to keep ahead of customer needs in the field.

Career highlights for SIGMA’s National Pipe Restraint Product Manager, Steve McDonald, have included:

| 2002 |

| SIGMA launched the 1st-ever 42” and 48” restraint devices for AWWA C900. Prior to this, 36” was the largest nominal restrainer size available in the marketplace. All three restraint sizes were compatible for use with mechanical joint fittings, bell x spigot pipe joint connections and PVC pressure fittings. |

| 2015 |

| This was the year when SIGMA brought to market the industry’s first 54”, 60” and 64” wedge-style restraining glands for ductile iron pipe to exhibit at AWWA’s Chicago show. |

| 2016 |

| At the AWWA show in San Diego, SIGMA unveiled the first-ever re-rounding bolt. This patented feature was developed for use with 54”, 60” and 64” restraints on ductile iron pipe to overcome any ovality issues in the field. |

| 2017 |

| At the AWWA show in Philadelphia, SIGMA introduced industry firsts exhibiting 54” and 60” wedge restraint glands and pipe bell harness assemblies for PVC pressured pipes. |

| 2019 |

| Engineering expanded the re-rounding feature to include on 42” and 48” wedge restraint glands for ductile iron pipes. |

| 2020 |

| The company continued to expand the re-rounding concept to incorporate 30” and 36” wedge restraint glands for ductile iron pipes. |

Steve McDonald commented on this heritage of innovation: “We’re proud to be at the forefront with new mechanical technologies for pipe restraint products. We’ve responded to the appetite we’ve seen from people working in the field and the needs created by the increase in pipe diameter and introduction of new materials.”